My path into Mechanical Design

I learned to repair cars, tractors, and bikes on our farm, often with limited resources. Every repair needed to be practical and efficient. This hands-on experience continues to guide my approach: understand the machine, identify the problem, and implement the simplest effective solution.

I also developed a passion for technical drawing. My path into engineering was non-traditional, as I learned through trades and hands-on work. This background gave me mechanical intuition, practical judgment, and the ability to design solutions that fabricators can implement efficiently.

In 1998, I lost my left arm in a motorcycle accident, but I remained committed to my career. I rebuilt, refocused, and returned to work within 18 months. While this experience does not define me, it strengthened my resilience. Employers benefit from my determination and ability to address challenges directly.

The prosthetic motorcycle arm I designed and built demonstrates my approach to problem-solving: understand the constraints, design an effective solution, and execute it properly. I apply this process to every project.

Rebuilding after a major life event taught me the importance of thorough planning, accepting support when needed, and moving forward with purpose. I apply this approach in my work through thoughtful decisions, clear communication, and a focus on long-term, reliable outcomes.

For the past nine years, I have also been a full-time single parent. While this occasionally slowed my career, it developed qualities that employers value:

• resilience

• patience

• responsibility

• clear priorities

• the ability to stay focused under pressure

I remain eager to grow, learn, and take on new challenges. As my parenting responsibilities change, I will be ready to pursue additional qualifications, accept greater responsibility, and further develop my expertise in mechanical design.

I remain committed to pursuing meaningful opportunities and continuous growth.

Professional Experience

I have over 15 years of experience in mechanical design, drafting, fabrication support, and the mining industry. My understanding of both engineering intent and the practical limits of fabrication, installation, and maintenance benefits employers.

I do not limit my work to the office. I visit sites, take measurements, inspect equipment, and communicate directly with those who build and install the work. I use a 3D scanner, precision tools, and hands-on experience to ensure designs are accurate before reaching the workshop.

In real‑world terms, this means:

fewer fabrication errors

clearer drawings

faster turnaround

practical solutions

Someone who understands the job from the ground up

I am resilient, focused, and efficient. I prioritise completing tasks properly, understanding problems thoroughly, and using time effectively.

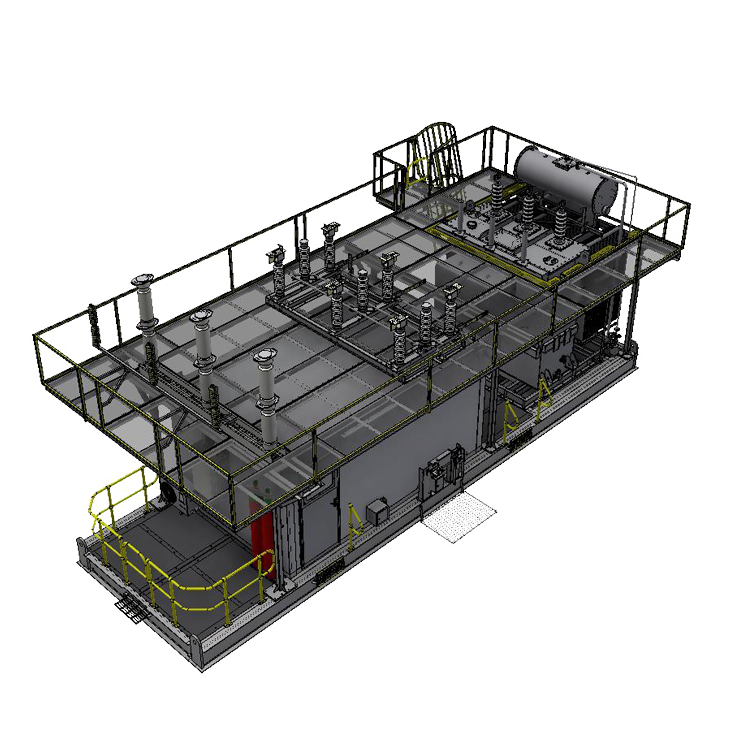

High‑Voltage Mining Equipment (Ampcontrol — 2012–2020, 2022–2025)

Over ten years of designing safety-critical high-voltage equipment have taught me precision, discipline, and clarity. These qualities strengthen any engineering team.

What I delivered:

IP enclosures, isolators, HT/LT ends, pump/fan starters

stainless steel IP‑rated enclosures

structural steel and sheet‑metal assemblies

standardised Opencut substation drawings

cable routing, bus bar layouts, mechanical/electrical integration

fabrication‑ready documentation that reduced workshop rework

The value this experience brings to your team:

Safety is my top priority in all aspects of my work, including on-site activities, design decisions, and risk identification. I adapt quickly to company documentation requirements and treat all intellectual property and internal information with the utmost respect and confidentiality.

Industrial & Fabrication Support (Forge Engineering — 2021–2022)

Forge provided a fast-paced, hands-on, and demanding environment, which was excellent preparation for delivering results under pressure.

What I worked on:

reverse‑engineered components

redesigns of worn or damaged parts

mechanical drawings for mining and industrial equipment

robotic welder interface design

fabrication‑ready documentation

AS/NZS compliance and lifting requirements

How this experience is reflected in my work:

I quickly identify missing details and collaborate with the appropriate team members to ensure the final design is accurate and buildable. When timelines are unrealistic, I address the issue early and propose practical solutions, maintaining clear communication and strong working relationships.

Structural & Access Systems (Ricbuilt — 2020–2021)

This role enhanced my ability to deliver fast, accurate work in a high-demand environment.

What I worked on:

custom aluminium structures

engineered access systems

lifting notes, disclaimers, installation details

Rapid design with limited information

adapting designs as materials changed

close collaboration with workshop staff

How this experience contributes to project success:

I collaborate with clients and team members to transform initial, unclear ideas into practical solutions. I ask targeted questions, address information gaps, and clarify the intended outcome. I then communicate this intent directly to fabricators and suppliers to ensure everyone understands the project requirements.

Access Platforms & Mining Support (INDCO — 2024–2025)

(including one year of subcontracting prior)

Working in a small, fast-paced team across multiple industries enhanced my versatility and adaptability.

What I worked on:

aluminium access systems

engineered platforms

custom mechanical components

reverse‑engineering

workshop‑friendly drawings

AS/NZS compliance

How this experience supports your operation:

I perform effectively across various job types when expectations and information are clear. In a communicative team, I manage workloads efficiently and facilitate coordination between designers, fabricators, and suppliers to keep projects practical and on track.

Earlier Career (1993–2012)

My early career established a foundation that continues to benefit employers:

mechanical intuition

communication skills

discipline

hands‑on understanding of fabrication, construction, and repair

the ability to work with anyone, anywhere

Experience in drafting, disability support, military service, and motorcycle mechanics has added depth to my professional approach.

The importance of this background:

My diverse experience has developed flexible communication skills and the ability to keep teams focused in high-stress situations. I can de-escalate problems, maintain positive momentum, and bridge communication gaps. I value cohesive, collaborative environments and work to resolve issues when teams become divided.